Fullymax focuses on the high rate discharge pouch batteries, including power batteries for electric aviation aircraft (eVTOL), electric power , drones, electronic cigarettes, fast charging batteries,12V/48V Start/Stop batteries and jump starter for car, RC professional remote control models and toy , military and special equipment, etc. FULLYMAX batteries are also widely used in smart home like sweeping robots, vacuum cleaners, small power tools, etc.; 3C consumer electronics like remote control handles, beauty equipment, portable projectors, etc., smart Bluetooth products, medical equipment ,ect

|

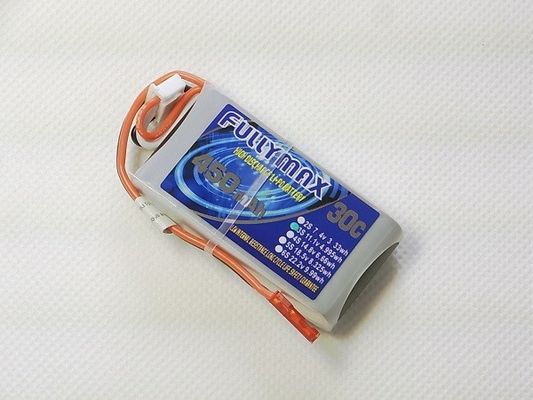

Fullymax 11.1V 450mAh 3S 30C li-po batteries with JST BEC connector

Fullymax 450mAh 3S Lipo is an 11.1V 450mAh LiPo battery. These 450mAh 3S LiPo batteries offer excellent blend of weight, power and performance. Available in a wide variety of capacities and voltages, there’s a battery perfect for almost any application, from indoor slow flyer to large-scale sport and aerobatic airplane models as well as micro to mid-sized helicopter models.

The Fullymax brand holds the core values of "Customer first Integrity and professionalism Scientific innovation Win-win cooperation". All batteries are tailored for various scales of the RC Models such as electronic cars, nitro cars, airplanes, vessels and also other models, toys, electric tools, electric bikes, electric autos, digital products etc. |

Related Product

For other configurations (without discharge plug) with same cell model, please refer below table.

| Battery pack | Model Description | Max cont. discharge | Burst (3Sec) | Dimensions H x W x L | Weight | Wh |

| FB450HP-1S | 3.7V 450mAh 1cell | 30C | 60C | 6x31x52mm | 16.00g | 1.67 |

| FB450HP-2S | 7.4V 450mAh 2cell | 30C | 60C | 10.8x32.3x60mm | 42.00g | 3.33 |

| FB450HP-3S | 11.1V 450mAh 3cell | 30C | 60C | 15x31.8x59mm | 54.00g | 5.00 |

Product Feature

- Stacking Technology Enables Single-Cell Capacities Of 450mAh.

- Capable of maximum continuous discharge rates up to 30C.

- Equipped with balancing leads and a connector that are compatible with most balancers and balancing chargers.

- Small in size and light in weight.

Application

Compatible with small indoor 3D, aerobatic, sport, or scale airplanes using Park 300 and Park 370 motors on 3S applications, etc.(Only if the voltage and the plug match, then it will fit.)

| The new plant will be located in the Dongjiang Bay Industrial Park, which will be a national high-end industrial park special for new energy, new information technology and intelligent equipment fields based on the “3+7” industrial park planning and deployment proposed by Huizhou relying on the Greater Bay Area, aiming to integrate Huizhou’s “1+4” industrial parks. The area of the new plant is estimated to be 30,000 square meters. With new high-end equipment and workshop environment, the goal is to build a high-end production line dedicated to high-end customers. |

| Quality Management System |

| Management Improvement according to international standards |

|

ISO9001 Quality Management System |

ISO14001 Environmental Management System |

Occupational Health And Safety Management System |

Hazardous Substance Process Management System |

Aeroepace Quality Systems AS9100D:2016 |

|

Safety and environmental Certificates capability&service |

|

| Performance Test Capability |

|

FAQ

| Q1. What are the diferences betwee high C-rate and low C-rate lithium? |

|

polymer (Li-Po) batteries.

|

| Q2. How is a Li-Po battery made? |

|

When a Li-Po battery is made, five main aspects should be considered carefully: (1). Battery Pack should have suficient strength, so that the polymer battery inside could be efectively protected from mechanical shocks; (2). The polymer cell should be fixedto the battery pack onits large surface area - no cell movement in the battery packshould be allowed; (3). No sharp edge components should be inside the packcontaining the polymer battery, and meanwhile, suficient insulation layer between wiring and the cell should be used to maintain multiple safety protection; (4). Ultrasonic welding is recommended for polymer tab connection to obtain low-resistance, high-reliability and light-weight properties;(5). Polymer packs shouldbe designed carefully so that no shear force is applied, and also, no heat is generated even when leakage ocurs for mishaps. PCM from electrolyte leakage should be isolated as perfectly as posible, and narrow distance between bare circuit patterns should be avoided.

|

| Q3.What are the gases inside a swelling cell, and are they toxic/dangerous? |

|

The gases vary depending on different situations: 1. If the gases were generated by electrolyte gas reaction, they would mainly beelectrolyte solvent components, for example: EC, DMC, EMS and so on; 2. If the gases were generated by overcharging, they would mainly be H2, CO, CO2,CH4 and so on; 3, If the gas were generated by improper sealing, they would mainly be H2, C2,H2and so on.

|

| Q4. Why do we need formation process? |

|

Organic solvents easily decompose on the negative electrodes during charging, leading to battery swelling, drop of cell capacity, and unsafety caused by active

|

| Q5. Why do Li-Po batteries bloat/swell? |

| The Li-Po batteries may bloat or swell due to the following reason: 1. Overcharging:Normally, the maximum charge voltage is 4.2V for RC batteries. If the batteries were overcharged beyond 4.4V, electrolytic oxidation process would happen, which generates mass gas leading to battery swelling. 2. Overheat:When discharging in high temperature or high C rate, the temperature of the inner part of the battery can be even higher, which gasify the electrolyte and results in swelling. 3. Shot-circuit.:If short circuit happened, the cell voltage would drop very fast and the electrolyte would be reactive to generate gases, leading to battery swelling. 4, Sealing:If sealed without proper processing, the battery cell would have water and air in, so that the electrolyte would be reactive to generate gases, leading to battery swelling. |